Rotor

Ideal for:Bakery,Patisserie

Single-chamber rotor ovens containing one or more trolleys enveloped by a flow of hot air, suitable for baking any bread and pastry product.

Revolving trolley oven

Designed with innovative technological solutions suitable for every bakery and pastry workshop.

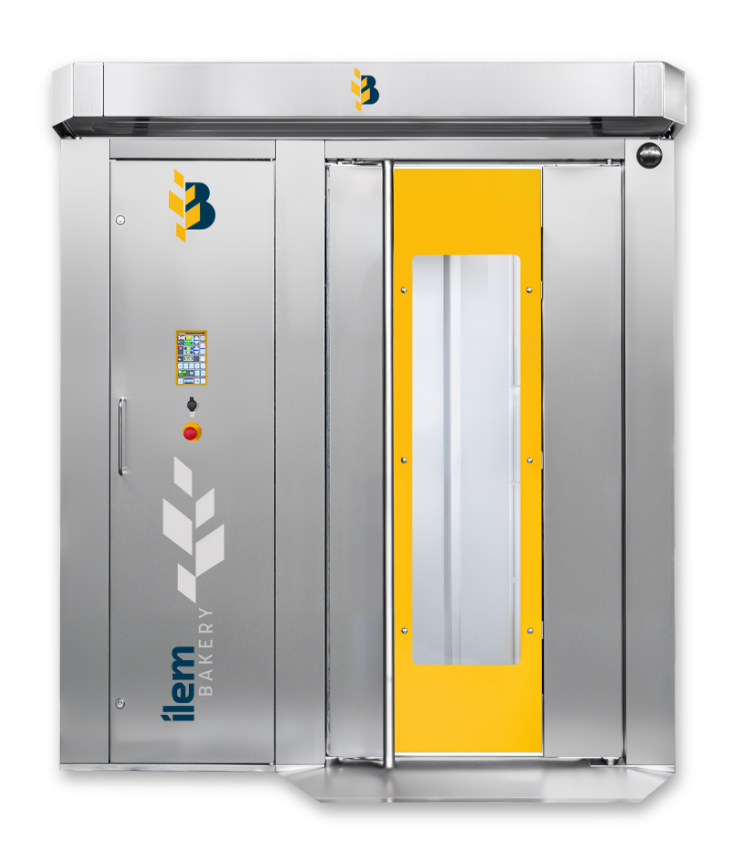

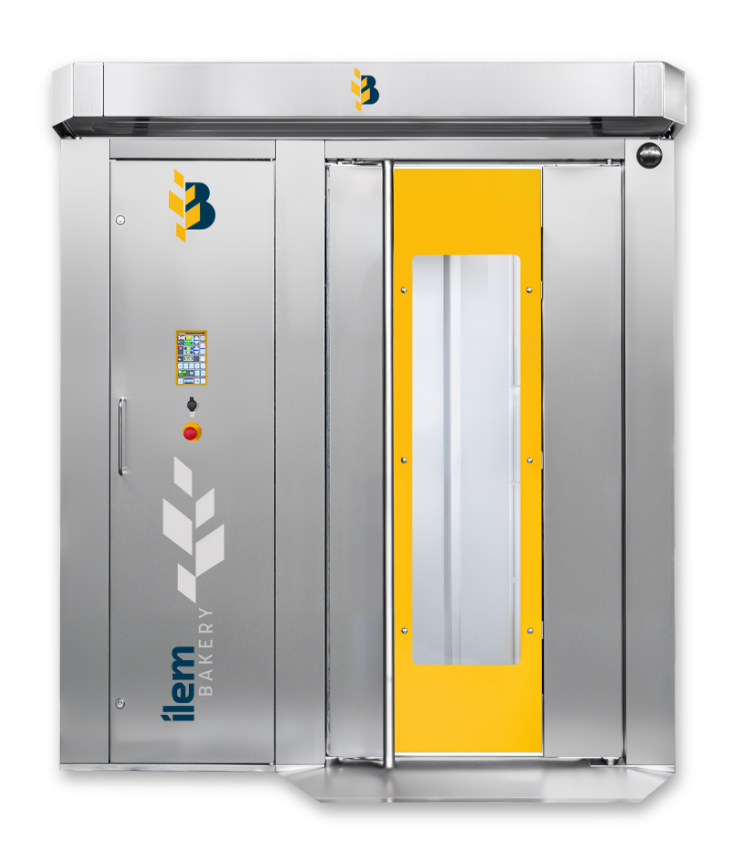

Model RP

REVOLVING TROLLEY OVEN WITH SIDE BURNER

It has three free perimeter sides for back wall support and combination with other ovens. Available in models 50 / 60 / 80 / 120 / 130.

Model RL

Model RS

Model RP

REVOLVING TROLLEY OVEN WITH SIDE BURNER

It has three free perimeter sides for back wall support and combination with other ovens. Available in models 50 / 60 / 80 / 120 / 130.

Model RL

Model RS

The advantages of ROTOR ovens

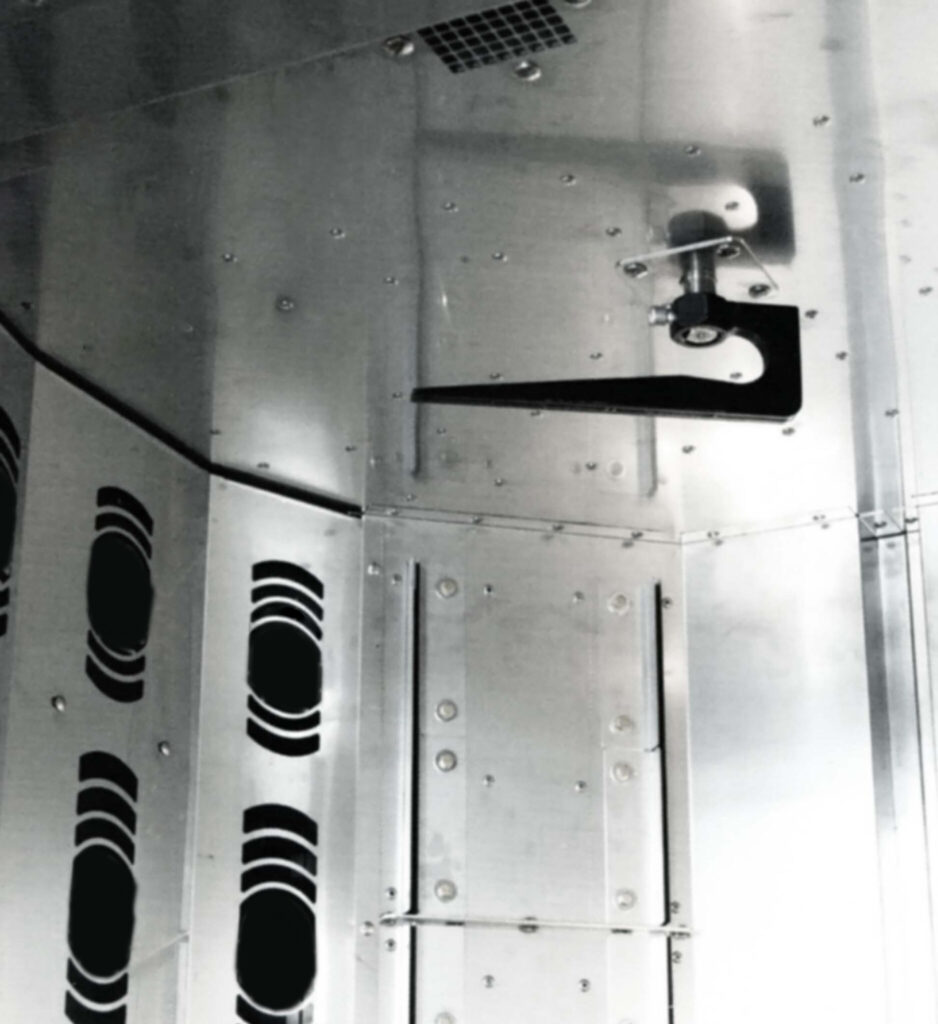

The baking chamber, made entirely of steel, contains, according to the various models, 9-place trolleys for baking trays of 40×60 cm. All models are equipped with a steamer for steam production. La rotazione del carrello, permette una buona omogeneità di cottura. Operation can be gas, diesel or electric.

Electric operation, with gas or oil burner

WIDE CHOICE OF 99 COOKING PROGRAMS

ADJUSTMENT OF UP TO 8 COOKING STEPS

TOUCH SCREEN CONTROL PANEL

ELECTROMECHANICAL CONTROL PANEL

DOUBLE SPEED AIR DELIVERY IN ROOM.

Rotor oven accessories

Revolving trolley

Simplifies the loading and unloading process, ensuring even distribution of products within the oven.

Turning platform

Gradually rotates products within the oven, ensuring that they are evenly exposed to heat.

Additional display

Provides additional information on oven status, such as internal temperature, remaining cooking time and other relevant information.

Professional and certified machines

Low Voltage Directive 2006/95/EC

Electromagnetic Compatibility Directive 2004/108/EC

Regulation (EC) No. 19352004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food.

There is no one piece of equipment better than another, but there is a right piece of equipment for every activity

The machines best suited to your business are those that make work easier and quality always excellent. Contact us to arrange a consultation meeting: we will evaluate together the most suitable solutions for your needs!

Our rotor oven catalogues

Download our catalogues to discover all the specifications of our rotor ovens